What is shaft laser alignment?

The process of using a laser to measure and correct the misalignment of two or more rotating shafts is known as shaft laser alignment. A highly accurate and efficient method of alignment, shaft laser alignment is used in many industries such as power generation, oil and gas, mining, manufacturing, food and beverages, paper and pulp, chemical processing, pharmaceuticals, plastics, and textiles, among others. Shaft laser alignment is a valuable tool for any industry that uses rotating machinery, which can help to improve efficiency, reduce costs, and extend the life of equipment.

When is shaft laser alignment needed?

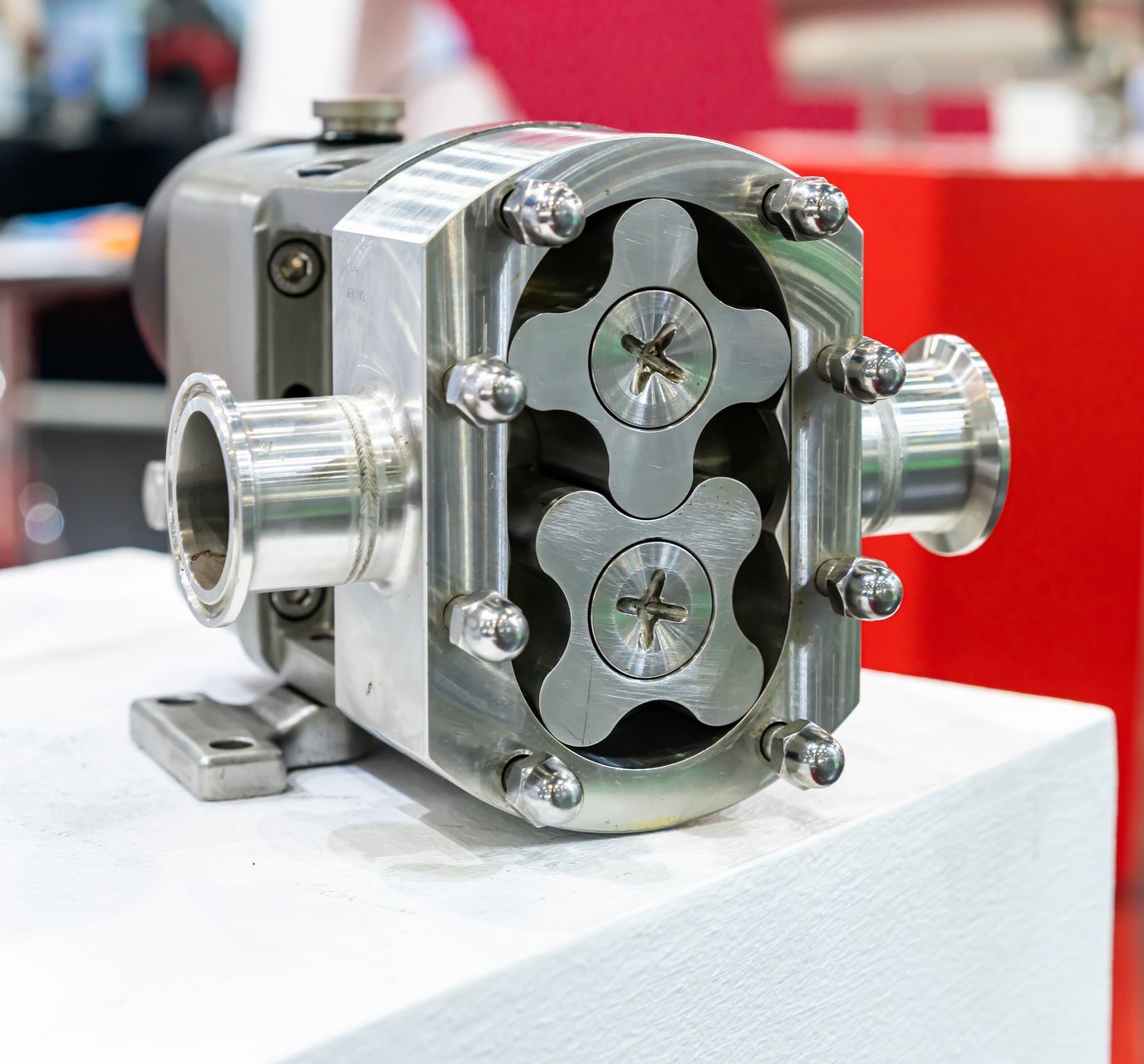

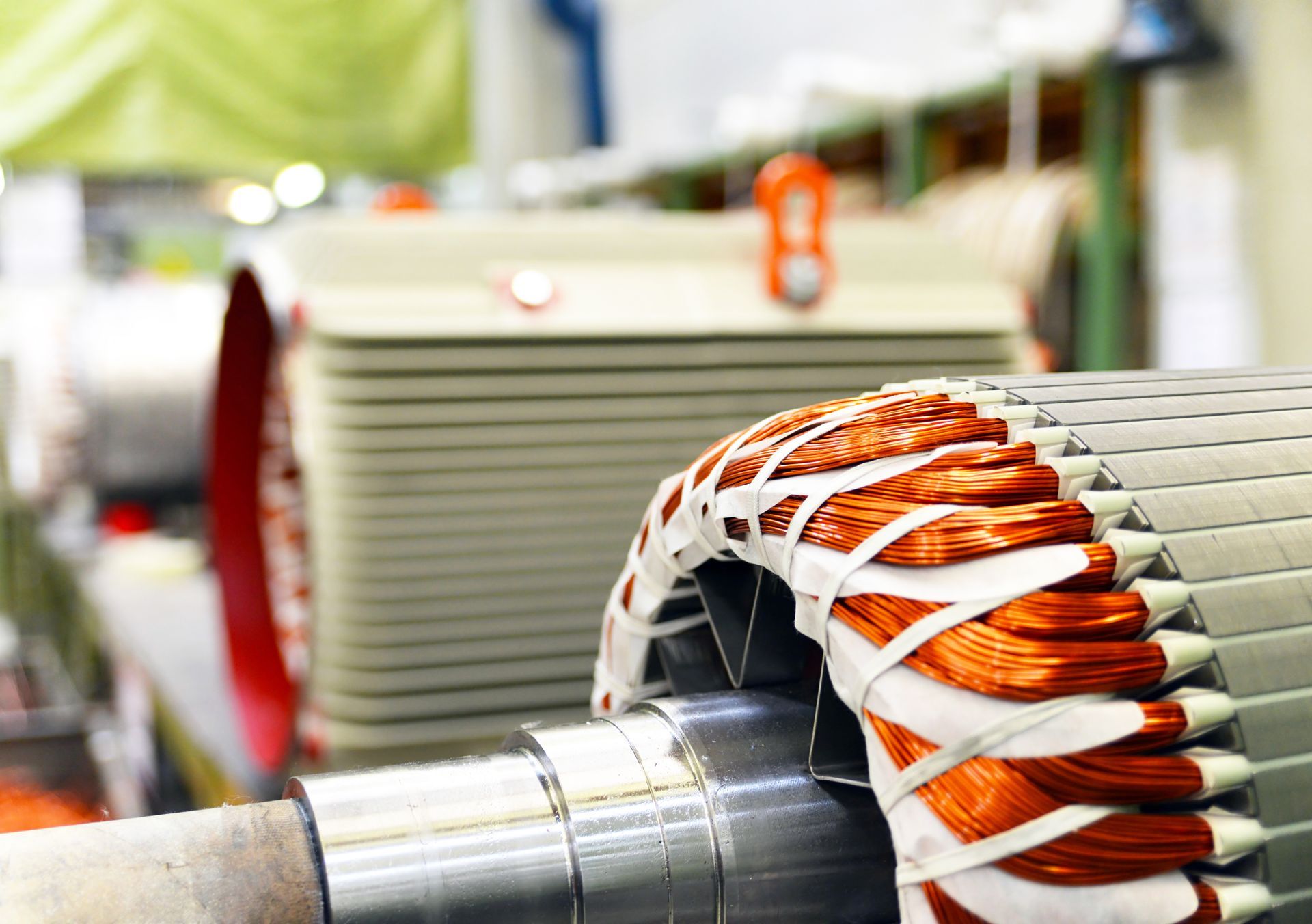

The process of shaft laser alignment is beneficial in improving electrical efficiency and the life of motors, fans, compressors, gearboxes, agitators, and pumps, as well as other machine components.

When shafts in machine components get misaligned, they can cause several problems, including:

- Increased vibration and noise

- Reduced bearing and seal life

- Increased power consumption

- Reduced machine efficiency

- Increased risk of failure

Shaft laser alignment is used to prevent these problems and extend the life of the rotating machinery.

How does shaft laser alignment work?

Typically, there are two laser transmitters and two receivers in a shaft laser alignment system. The transmitters are attached to the shafts to be aligned, and the receivers are placed on stands or brackets. The transmitters emit laser beams that are detected by the receivers, which measure the position of the laser beams and calculate the misalignment of the shafts.

Misalignment results are then displayed on the alignment system software, which also provides instructions on how to correct it. The misalignment can be corrected by adjusting the feet of the machines or by using shims.

What are the benefits of shaft laser alignment?

There are many benefits to using shaft laser alignment, including:

- Accuracy: Shaft laser alignment systems are highly accurate and can measure misalignment to within a few thousandths of an inch.

- Efficiency: Shaft laser alignment systems are quick and easy to use. A typical alignment can be completed in 15-30 minutes.

- Reliability: Shaft laser alignment systems are reliable and accurate, even in harsh environments.

- Versatility: Shaft laser alignment systems can be used to align a wide variety of rotating machinery, including pumps, fans, compressors, turbines, and motors.

What are the uses of shaft laser alignment?

A wide variety of industries can use shaft laser alignment for regular maintenance and continuous working of machinery. For example, in:

- Power generation: to align the shafts of turbines, generators, and other rotating machinery in power plants, to ensure that the turbines and generators operate efficiently and reliably.

- Oil and gas: to align the shafts of pumps, compressors, and other rotating machinery in oil and gas facilities. This helps to prevent vibration and noise, which can be a safety hazard in oil and gas facilities.

- Mining: to align the shafts of conveyors, crushers, and other rotating machinery in mines in order to reduce downtime and improve efficiency.

- Manufacturing: to align the shafts of machine tools, production equipment, and other rotating machinery in factories. This helps to improve the quality of products and reduce scrap rates.

- Food and beverage: to align the shafts of mixers, conveyors, and other rotating machinery in food and beverage processing plants, to ensure that food and beverage products are manufactured safely and hygienically.

- Pulp and paper: to align the shafts of conveyor belts, rollers, and other rotating machinery in pulp and paper mills.

- Chemical processing: to align the shafts of pumps, compressors, and other rotating machinery in chemical processing plants.

- Pharmaceutical: to align the shafts of mixers, conveyors, and other rotating machinery in pharmaceutical manufacturing facilities.

- Plastics: align the shafts of extruders, injection molding machines, and other rotating machinery in plastics processing plants.

- Textiles: to align the shafts of spinners, looms, and other rotating machinery in textile mills.