What is condition monitoring and when is it used?

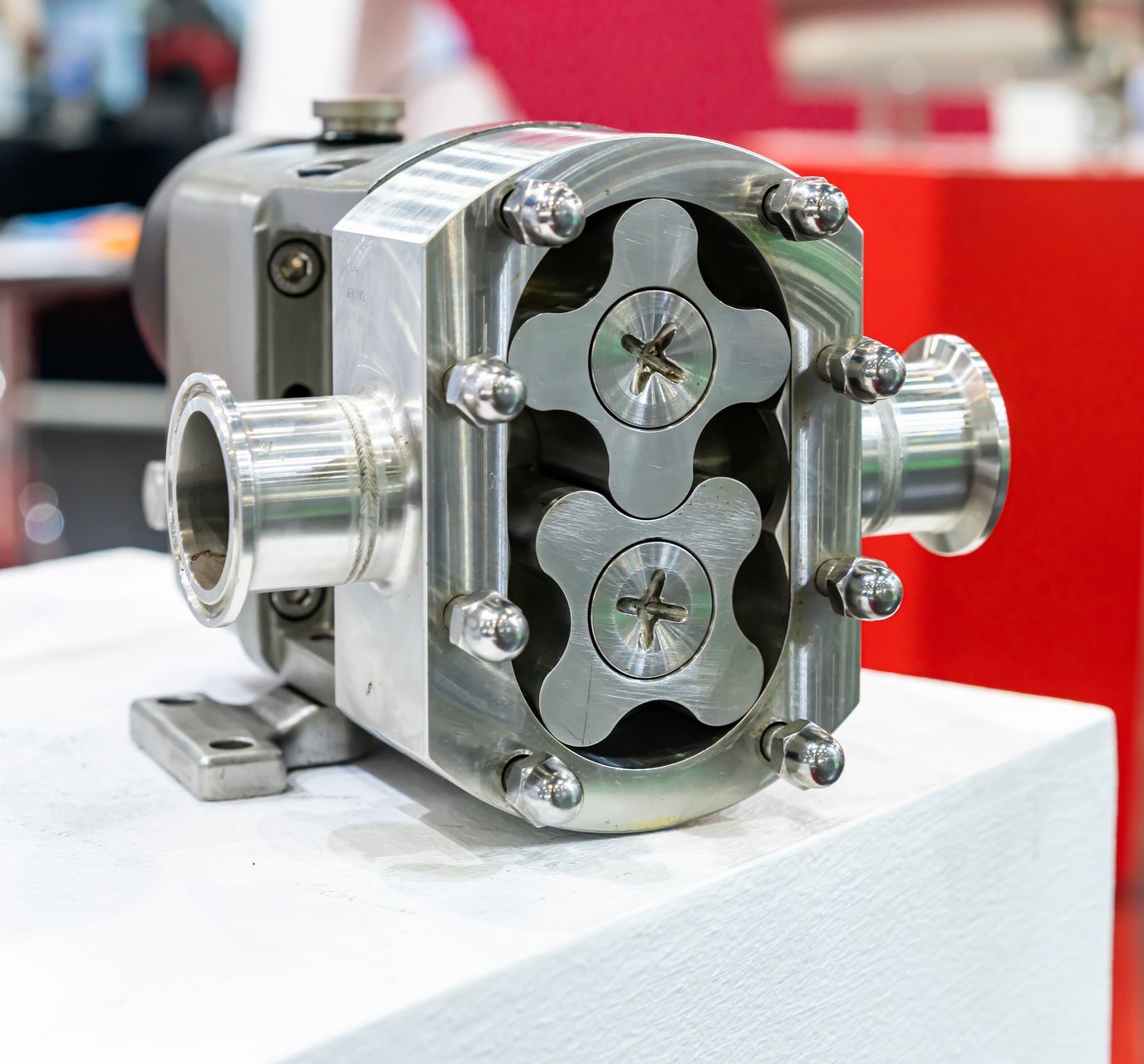

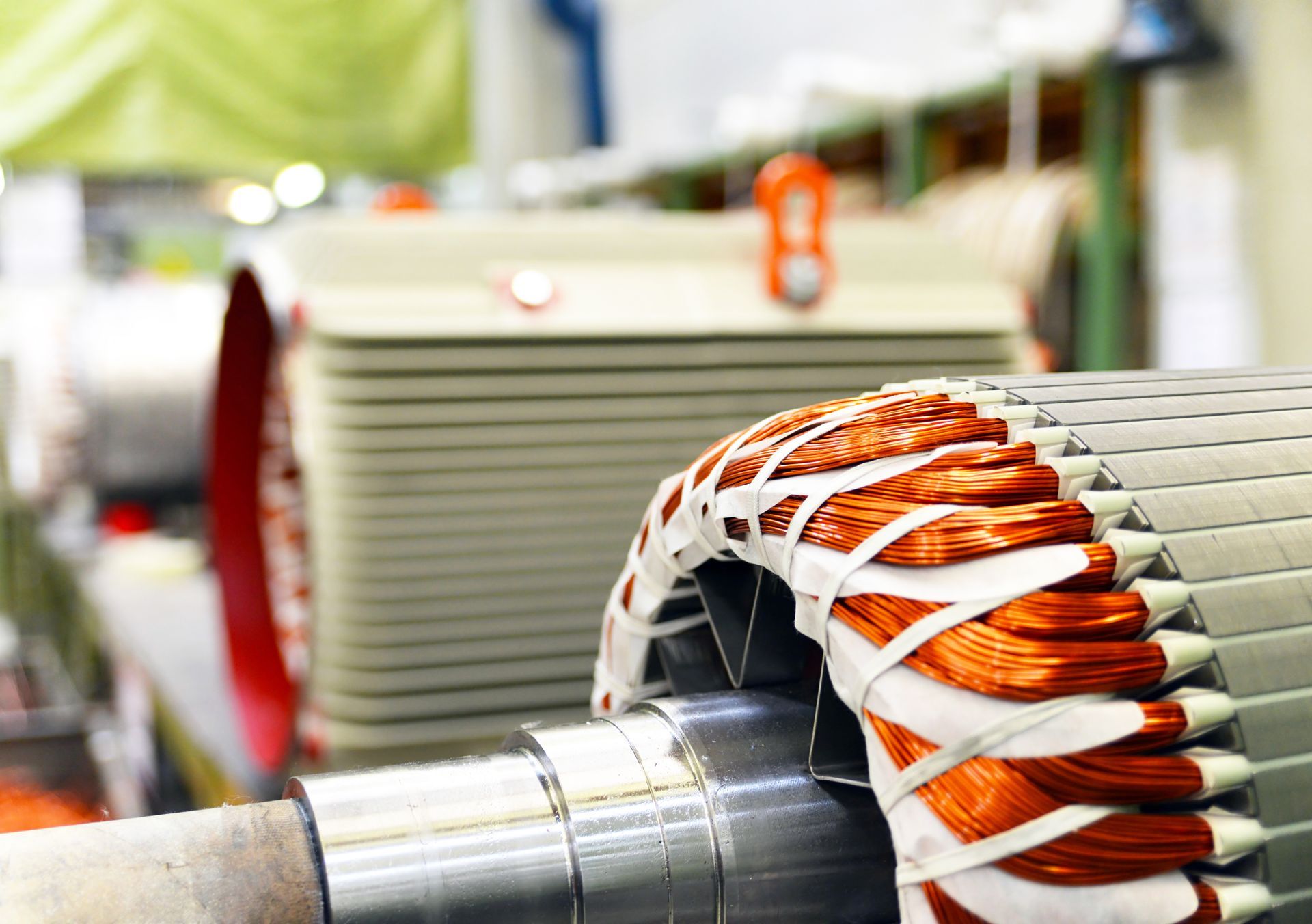

The process of measuring and monitoring certain parameters of a machine, such as vibration, temperature, and oil condition to detect any changes that may indicate a developing fault or malfunction is known as condition monitoring. This is an essential part of predictive maintenance, as it allows for timely and preventive actions to avoid further damage and unplanned downtime. Condition monitoring can be applied to various types of equipment, such as rotating machinery, auxiliary systems, compressors, pumps, motors, presses, and more.

One of the most common methods of condition monitoring for rotating machines is vibration analysis. This method involves measuring the vibration signals from the machine using sensors, such as accelerometers or eddy-current transducers, and analysing them to identify the source and severity of the imbalance or misalignment. Vibration analysis can also reveal other problems, such as bearing defects, gear wear, looseness, and resonance among others.

Another method of condition monitoring is lubricant analysis. This method involves sampling and testing the oil or grease used in the machine to check its physical and chemical properties, such as viscosity, acidity, contamination, and wear particles. Lubricant analysis can provide information about the condition and performance of the machine components, such as bearings, gears, seals, etc., as well as the lubrication system itself. Lubricant analysis can also help optimise the lubrication intervals and reduce the waste of lubricants.

Other methods of condition monitoring include acoustic emission, infrared thermography, ultrasound, motor current signature analysis, and model-based voltage and current systems. These methods use different types of sensors and techniques to measure various aspects of the machine's operation and behaviour, such as noise, temperature, pressure, current, voltage, etc. These methods can complement or supplement the vibration analysis and lubricant analysis methods to provide a more comprehensive and accurate diagnosis of the machine's condition.

Dynamic balancing is a related concept to condition monitoring. It is a method of adjusting the mass distribution of a rotating body to reduce or eliminate the vibration caused by unequal centrifugal forces. Dynamic balancing is usually performed by adding or removing weight from the rotating parts until the vibration is minimized. Dynamic balancing can improve the performance and efficiency of the machine, as well as extend its lifespan and reduce its noise.

It can be done in two ways: on-site or off-site. On-site balancing is done on the machine while it is running at its normal speed and load. This method requires special equipment and software to measure the vibration and calculate the correction weights. Off-site balancing is done on a separate balancing machine that spins the rotating part at a controlled speed and measures the imbalance using electronic equipment. This method requires removing the rotating part from the machine and transporting it to the balancing facility.

Condition monitoring and dynamic balancing are important practices for maintaining and improving the reliability and performance of industrial machines. They can help prevent failures, reduce downtime, save costs, enhance safety, and increase productivity. By using various methods and techniques to measure and analyse different parameters of the machine's operation and behaviour, they can provide valuable information and insights for making informed decisions and actions regarding machine maintenance and optimisation.