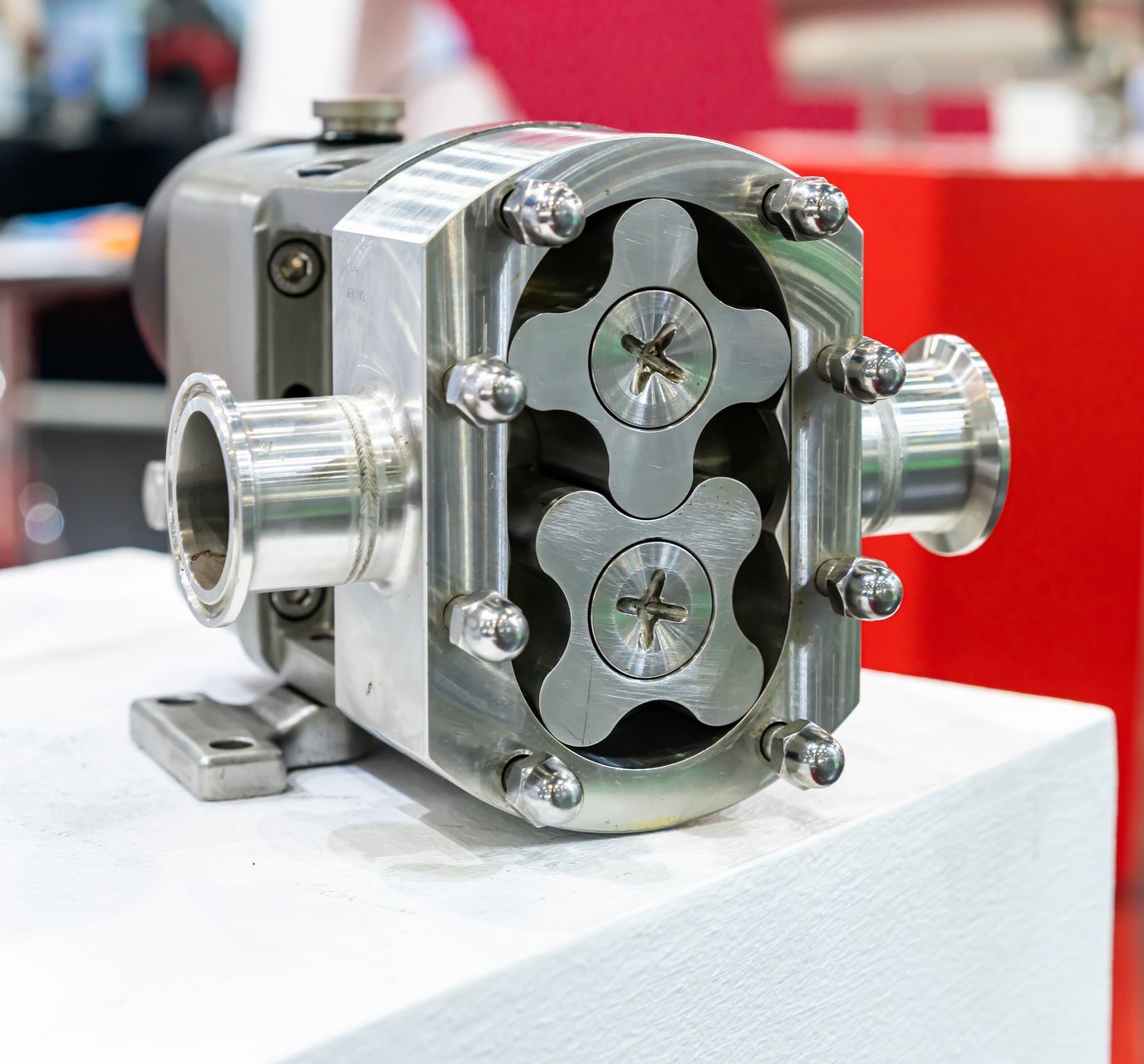

Gearboxes: A Mechanical Marvel

Gearboxes play a pivotal role in our everyday lives, yet often remain hidden within the depths of the machines they power.

Typically, a gearbox is a mechanical device that transmits power from one part of a machine to another, altering the speed, direction, or torque of the motion in the process. As an example, a gearbox basically serves as the intermediary that ensures the engine in your car can deliver power to the wheels effectively. It does this by using a combination of gears, each with a distinct size and arrangement.

What are the mechanics of Gears?

Gears are the heart and soul of any gearbox. They come in various shapes and sizes, each with a unique set of teeth. The teeth on gears are precisely designed to mesh with one another, allowing for the transfer of rotational motion.

Gears can be classified into two main types:

1. Spur gears are the most common type of gears, featuring teeth that are straight and parallel to the axis of rotation. They provide smooth and efficient power transfer.

2. Helical Gears have angled teeth, which makes them run more smoothly and quietly. They are often used in applications where noise reduction is crucial.

One of the primary functions of a gearbox is to change the gear ratio, which is the relationship between the number of teeth on the input gear (the one connected to the power source) and the number of teeth on the output gear (the one connected to the load). By altering this ratio, a gearbox can increase or decrease speed, torque, or direction as required by the machine.

What are the applications of gearboxes?

Gearboxes are versatile and find applications in a multitude of industries. Here are a few notable examples:

1. Automotive Industry: In automobiles, gearboxes are ubiquitous. They enable the engine to efficiently transfer power to the wheels at different speeds, allowing for acceleration, deceleration, and maintaining a steady cruising speed.

2. Manufacturing: In the manufacturing sector, gearboxes are used in conveyor systems, automated machinery, and production lines to regulate the speed and precision of various processes.

3. Wind Turbines: Gearboxes in wind turbines play a critical role in converting the low-speed rotation of the blades into high-speed motion for electricity generation.

4. Heavy Machinery: Construction and mining equipment often rely on gearboxes to handle heavy loads and perform various tasks, from digging to lifting.

5. Aerospace: Aircraft require complex gearboxes for functions like adjusting the flaps, landing gear, and even in the operation of jet engines.

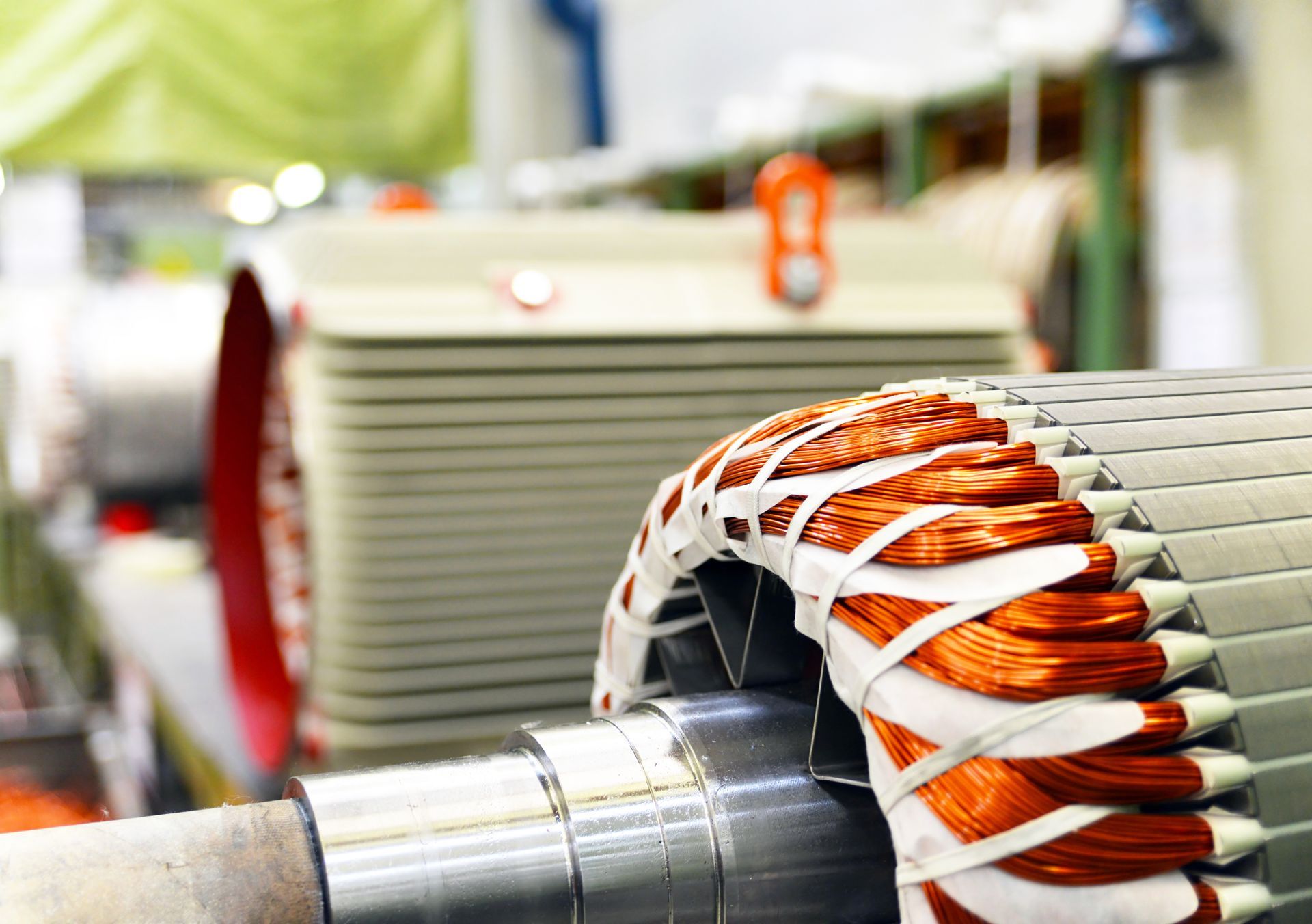

Designing gearboxes can be a complex task, with engineers needing to balance factors such as efficiency, durability, and noise reduction. Precision engineering is critical to ensure smooth operation and longevity. Additionally, regular maintenance and lubrication are essential to prevent wear and tear on gears, which could lead to reduced performance or even failure.