T: 0151 647 9997

Fabrication: Transforming Ideas into Reality

In the world of engineering and manufacturing, the term "fabrication" holds a special place. It's the process where raw materials are shaped, assembled, and transformed into useful structures or machinery, effectively bridging the gap between design and reality. While on the one hand, it requires cutting-edge technology, on the other hand, it is an art that requires skilled hands. It has diverse applications and requires immense capabilities.

What is Fabrication?

Fabrication is a multifaceted art, where materials like steel, aluminium, and various alloys are moulded into intricate structures. This moulding requires precision, creativity, and technical expertise, all rolled into one. From concept to execution, the process is a journey of constant innovation.

At MR Engineering, our range of projects completed includes carrying out repairs to/adapting existing and creating new: Fans/Impellers, Motor/Pump Skids, Access/Working Platforms/Walkways, Staircases/Access Ladders, Handrails/Safety Barriers and safety Fences/Screens, Bunds, Centre Columns, Dewatering Screens, Grit Rakes, Pipework, Hoppers, Tanks, Transfer/Storage Vessels, Rollers/Conveyors, and Workbenches/Trolleys.

The projects we undertake are incredibly diverse. We tackle a wide array of challenges, from creating new installations to repairing and adapting existing ones. Here's a snapshot of the projects that our skilled team has successfully brought to life:

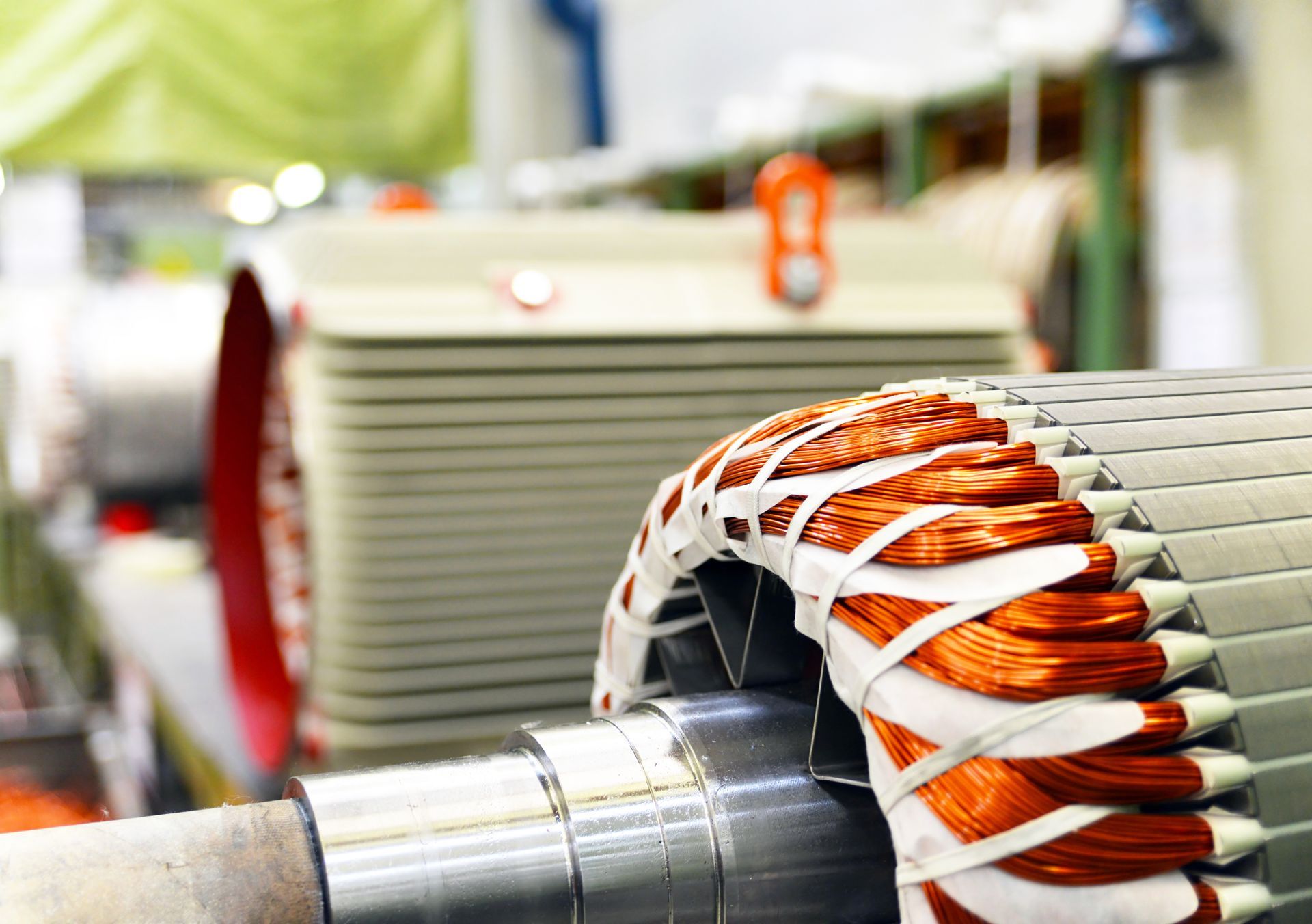

Fans and impellers are vital components in various industrial processes. Proper fabrication ensures their efficiency, longevity, and reliability.

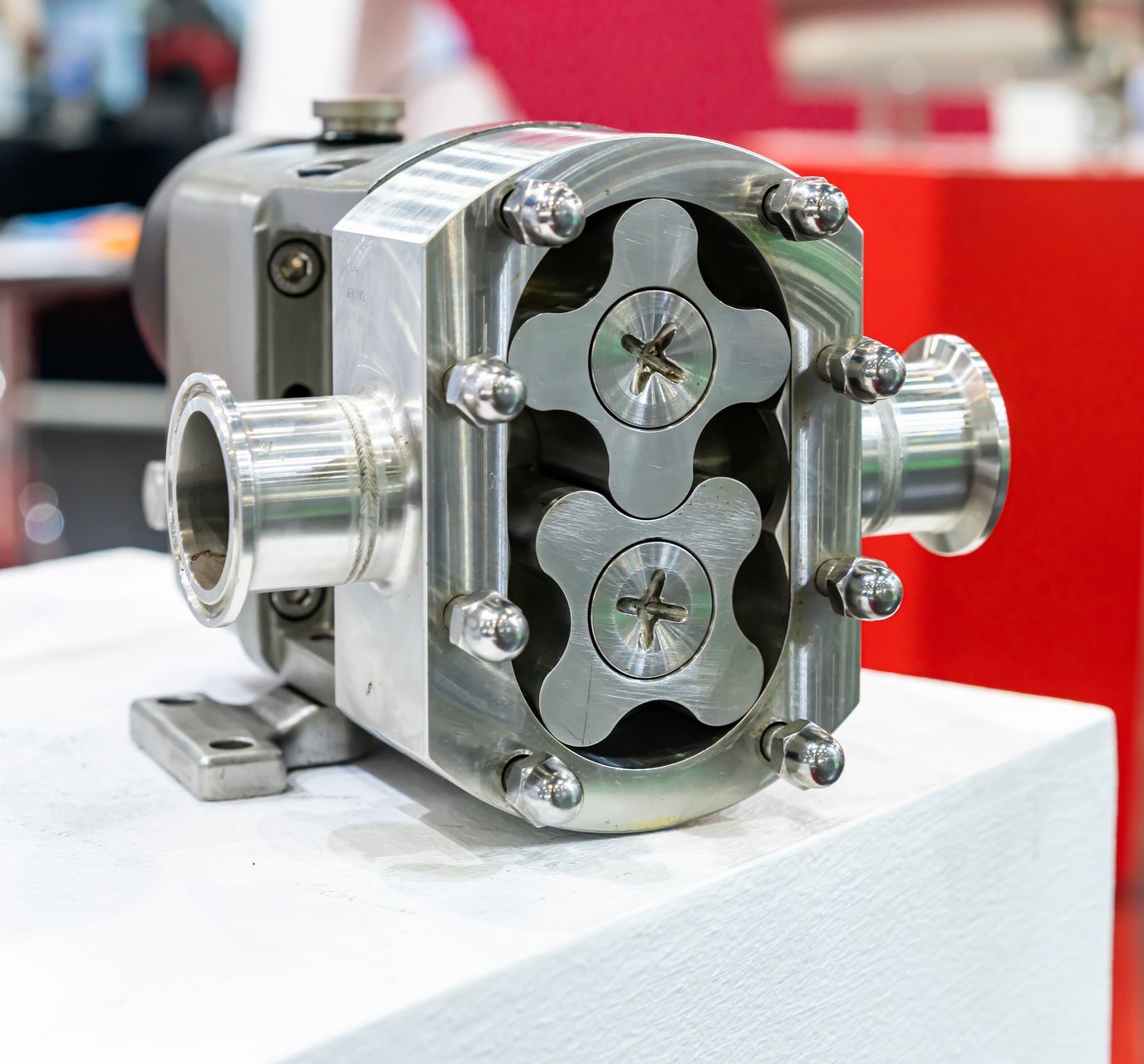

A well-designed motor or pump skid is crucial for the proper functioning of machinery in industrial settings. Fabrication ensures that these skids are sturdy and built to last.

Safety and accessibility are paramount in any industrial environment. Our fabrication expertise extends to the construction of sturdy platforms, walkways, staircases, and access ladders.

Safety is a priority in any work environment. Our team crafts safety features like handrails, barriers, fences, and screens to protect workers and equipment.

Bunds are containment structures designed to prevent the spillage of hazardous materials. Our fabrication team constructs robust bunds to safeguard the environment and workers.

Centre Columns, Dewatering Screens, Grit Rakes, and Pipework are essential components in various industrial processes. Fabrication ensures that they meet specific requirements and function flawlessly.

Hoppers, tanks, and vessels are key elements in material handling and storage. Our team fabricates these structures to be durable and efficient.

In manufacturing and logistics, efficient material handling is essential. Our expertise extends to fabricating rollers and conveyors that streamline the movement of goods.

Custom workbenches and trolleys are important components in various industries. We design and fabricate these tools to suit specific needs, enhancing productivity.

Meeting industry standards

In the world of fabrication, adhering to industry standards and ensuring the quality of the final product is paramount. The projects we undertake are executed with precision, and every piece undergoes rigorous quality control to meet and exceed industry standards. Whether it is constructing a heavy-duty industrial tank or a delicate, intricate structure, we pride ourselves on delivering excellence in fabrication.

Cutting-Edge Technology and Expertise

While the art of fabrication is deeply rooted in craftsmanship, it is also supported by cutting-edge technology. Our team combines traditional techniques with the latest tools and software to ensure that every project is executed with precision. This fusion of tradition and technology results in structures that are not only robust but also aligned with modern industry needs.

Fabrication is more than just shaping metal; it is also about transforming ideas into tangible, functional structures. From essential safety features to intricate components that power industries, our team has successfully completed an array of projects, showcasing our commitment to precision, quality, and innovation. Our passion for fabrication drives us to continually push the boundaries, ensuring that we meet the ever-evolving demands of the industrial landscape.

Contact Us

M R Engineering Group

107 ‑ 125 Bridge Street

Birkenhead

Merseyside

CH41 1BD

(Sat Nav Postcode: CH41 1AT)

© Copyright 2023 M R Engineering. All Rights Reserved.