T: 0151 647 9997

What Are Electric Motor Repairs

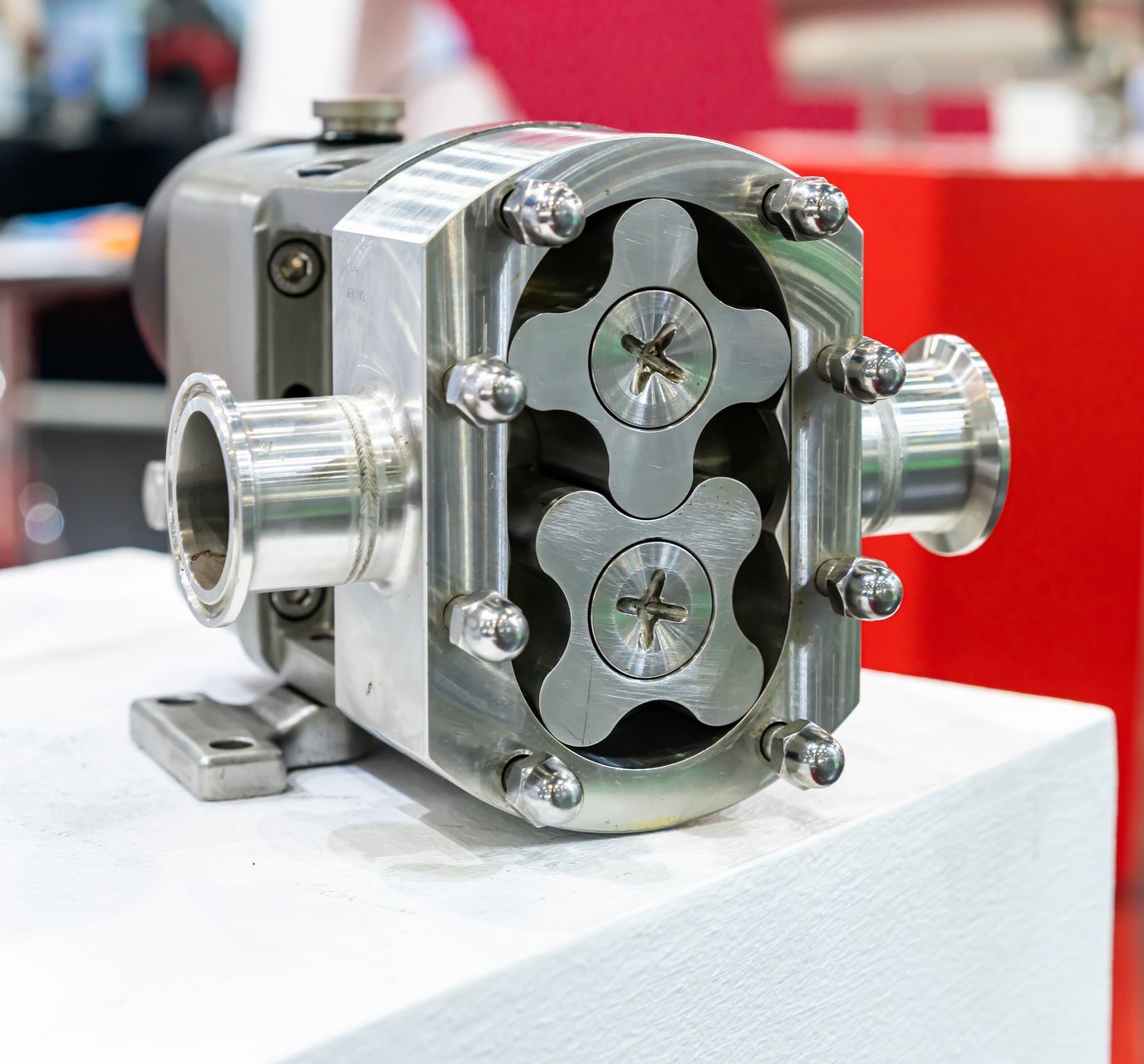

Repairing rotating plant equipment

Electric motors are essential components of various machines and equipment including industrial machinery, HVAC systems and countless other appliances. Maintaining, troubleshooting, and restoring electric motors and rotating plant equipment are necessary aspects of their efficient operation. When these motors malfunction or wear out, repairs are necessary to restore their functionality and prevent the need for costly replacements.

As such, it is a great idea to maintain the equipment regularly and consult an expert for any repairs and restoration work.

Some essential repairing components include the following:

When bearings in electric motors wear out due to friction and heat, bearing replacement is required. Replacing such worn-out bearings is one of the most common repairs to ensure smooth operation.

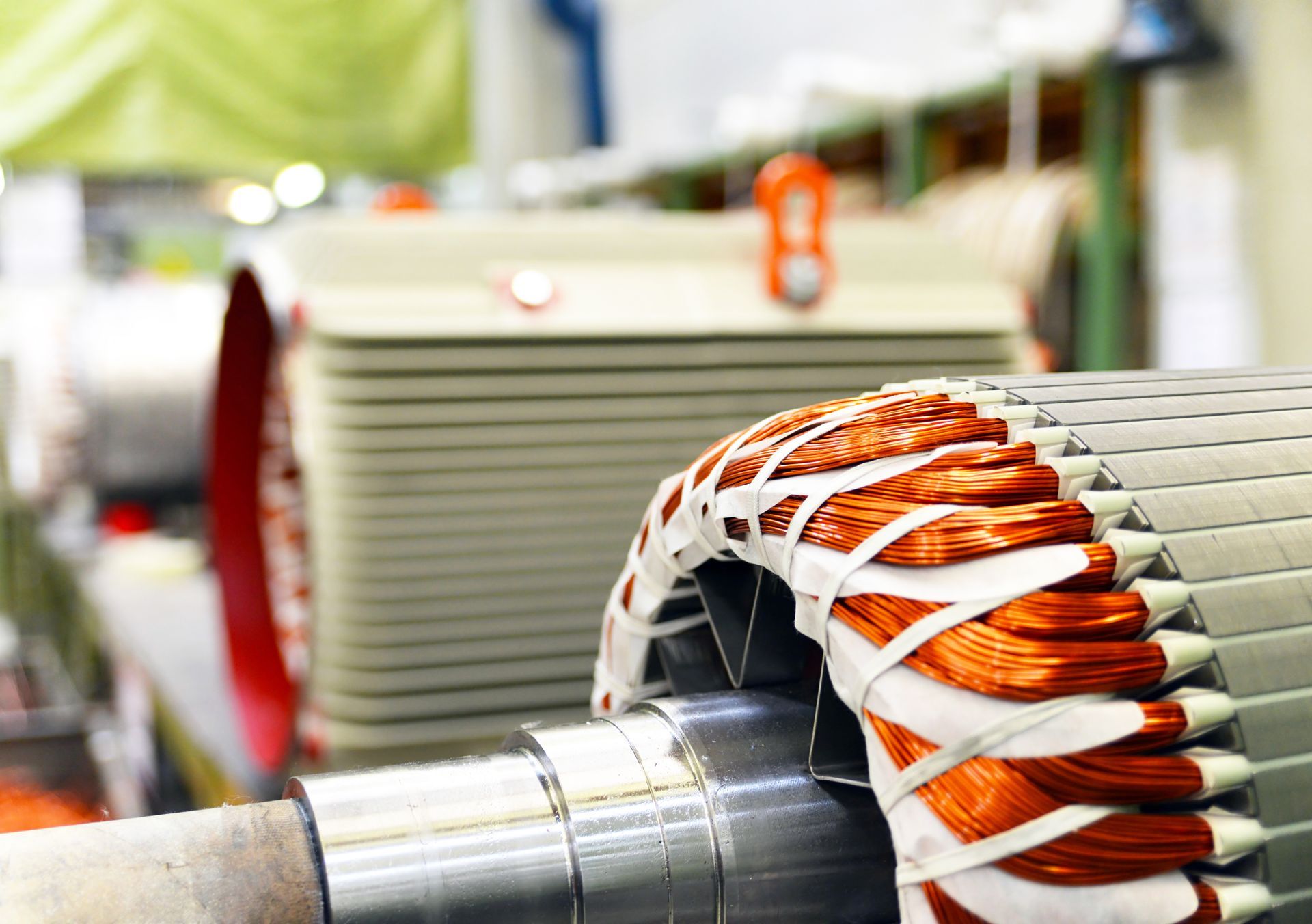

If and when motor windings are damaged or burnt out, rewinding becomes necessary, involving the removal and replacement of the old windings. This will restore the motor’s electrical efficiency.

Rotor and stator repairs are necessary components of an electric motor. While this is a complex job it is extremely crucial to restore motor performance.

Some electric motors, such as DC motors, can wear out brushes, which must be replaced because they are responsible for conducting electricity to the rotor.

Routine maintenance also means cleaning and lubricating all the moving parts to prevent excessive wear and tear.

Proper alignment of the motor/equipment is essential to prevent vibration and wear. When a motor experiences excessive vibration, it may also require balancing to ensure smooth and efficient operation.

Cooling and control systems can periodically require repairs. Electric motors often have cooling systems that may include fans or coolant circulation to prevent overheating. To ensure the longevity of the components, repairing or replacing them may be required. Control systems include capacitors or relays, and these may need repairing or replacement to resolve motor problems. These might look like easy jobs, but for the sake of safety, it is always a good idea to get a professional to perform them.

Faulty wiring, switches, or connections can also cause electric motor problems and skilled technicians are required to troubleshoot and rectify these.

Sometimes, a motor can be controlled by a variable frequency drive (VFD) or inverter, and these might need troubleshooting or repairs. Once again these must be undertaken by professionals.

Technicians sometimes use vibration analysis tools to detect and repair vibration issues in the motor and may also conduct periodic insulation resistance testing to ensure the motor windings are adequately insulated to prevent electrical faults.

It should go without saying that electric motor repairs should be conducted by qualified professionals who have the expertise and experience to diagnose and fix motor issues safely and effectively. Regular maintenance and prompt repairs can extend the lifespan of electric motors and reduce the risk of costly downtime in industrial and commercial applications.

It is a good idea to hire technicians with relevant accreditation (such as the Association of Electrical and Mechanical Trades or AEMT, a United Kingdom trade association representing engineering companies in the service and repair industry), as well as those who employ quality assurance and best practices across all of their services.

Contact Us

M R Engineering Group

107 ‑ 125 Bridge Street

Birkenhead

Merseyside

CH41 1BD

(Sat Nav Postcode: CH41 1AT)

© Copyright 2023 M R Engineering. All Rights Reserved.